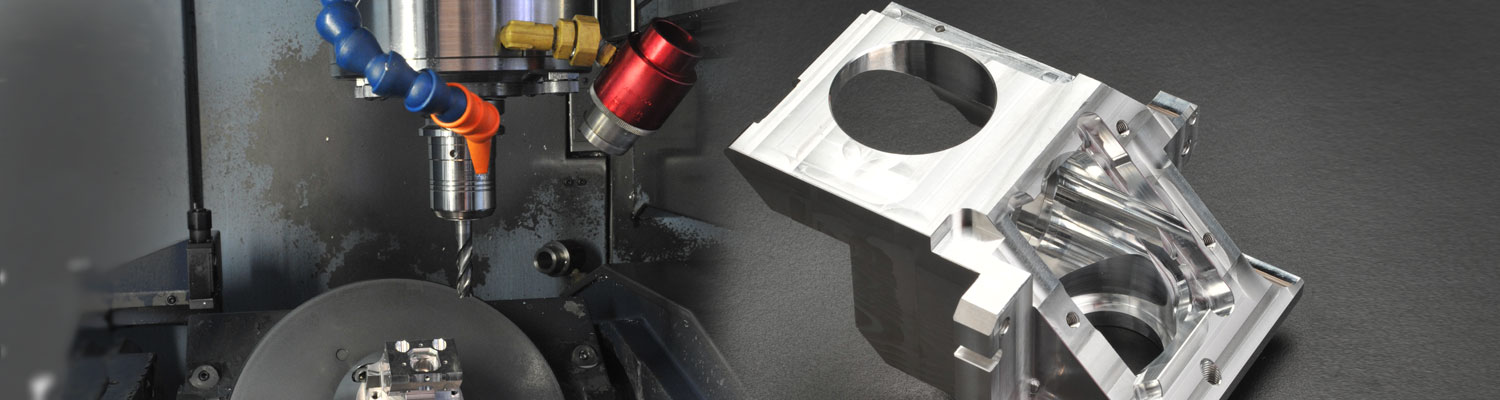

5-AXIS CNC MACHINING SERVICE

WHAT IS 5-AXIS MILLING?

The difference between a 5-axis CNC machining system and a lower level, such as a 2-axis system, is as much as the night and day comparison between a Ford Escort commuter car and a Porsche. Yes, they both get you to your destination, but how you get there and with what quality are miles apart from each other. In fact, the detail capability of 5 axis CNC machining is so exponential, many have likened it to an art tool versus just plain manufacturing and production alone.

TECHNICAL BACKGROUND

Mechanically, the 5-axis CNC system incorporates the use of five different motion axiss or points of pivot in its operation. Because of the added versatility and range of motion, the tools are able to produce complex products that involve curvature, work, and depth not possible with lesser number axis systems. In addition, 5-axis systems are able to produce a high level of minute accuracy as well. No surprise, industries like aviation which require parts built and fabricated to high detail find the 5-axis approach ideal for their needs.

IS 5-AXIS CNC MACHINING VIABLE WITH 3-D PRINTING?

There’s a very strong argument brewing that 3-D Printing as it advances will ultimately make CNC machining in any form obsolete. It’s important to remember that the most 3-D Printing is able to provide right now is soft material markups. Where CNC machining can easily deal with metal stock material of different hardness as well as rock and other high-density materials, 3-D Printing is generally limited to plastics and similar soft materials that respond quickly to heat and delicate tools. In this regard, 3-D Printing is great for modeling and showing what an idea could look like physically, but it doesn’t compare to CNC machining that actually produces a part that can go into production and be used in a metal assembly.

THE BENEFITS OF 5-AXIS CNC MACHINING

5-Axis CNC machining allows complete machining to be undertaken at the same time, without the need to stop and adjust. Because 5-axis CNC machine covers up to five sides of a part in one operation, it ensures much tighter tolerances are upheld, for ultimate accuracies in the alignment of features from one side of the part to another. The result of 5-axis milling is evident in product quality.

The first and foremost benefit of a 5-axis approach is the efficiency of the overall custom build process. Where lower-level systems would require multiple stages and even multiple machines to produce the finished part, the 5-axis approach can do all the same on one system and machine. This reduces the amount of fabrication time involved and produces a complete part in one place faster.

As noted earlier, the accuracy is far greater with a 5-axis system, which also means less opportunity for error and a cleaner application of milling or cutting to the original design. This is particularly important when crafting sections of a part that involve depth and curvature in multiple directions.

The wear and tear on a 5-axis machine system is far less than lower axis models because there is less change out of systems and swapping of parts. The machine operates in one cycle and motion with the fabrication, reducing the strain on its working components with a teardown and startup.

Limited workspace is also a side benefit of a 5-axis system. For manufacturing shops who need custom work on-site but don’t have a large amount of room to maintain a full CNC office with multiple systems, the 5-axis approach provides the same resources with a far smaller physical footprint.

UNDER-UTILIZATION IS COMMON

The downside of 5-axis CNC machining comes in its practical worth. If a manufacturing shop doesn’t have the personnel on hand or the demand to fully utilize such a system to its full capacity, then there’s not really a good point in making such an investment in-house. In fact, if the need for high-quality CNC machining is sporadic, it’s a far better approach to outsource the work with a third party who would have the expertise, can apply it efficiently, and produces the needed part stock in a timely manner for what is needed.

The fact is, running a professional 5-axis production shop takes a lot of investment. Folks have to go through an extensive amount of training, the company has to invest in the equipment and software, and a learning curve applies to what is needed by a specific company and its criteria for production. What works for a vehicle engine factory may not be sufficient for an aerospace design facility. If the investment is not going to pay for itself in a sufficient manner, a company could find itself in a boondoggle with in-house 5-axis CNC machining.

WORKING UP TO A SOLID DELIVERY SYSTEM

Evden Enterprises fills the gap for many manufacturing shops, ranging from aviation to medical, with outsourced 5-axis CNC machining expertise. Because Evden’s specialists are heavily trained in CNC machining of all types, and Evden has already done the hard work being invested in CNC technology and its applications, clients are able to take full advantage of Evden Enterprises services without the sunk expense of trying to ramp up internally (which could take years to achieve). There’s no reason to struggle to achieve high-quality CNC machining on demand; Evden Enterprises can provide what’s needed while your business focuses on what it manufactures best.

OUR EQUIPMENT AND CAPABILITIES

We utilize state-of-the-art 5-axis CNC machining centers with multiple pallet systems (up to 40 pallets), giving us the flexibility to have many different parts running simultaneously. This allows us to be flexible enough to satisfy customer delivery requirements. Our equipment includes:

>> (2) Matsuura MAM 72-3VS, 5-axis machining centers with 40 pallets

>> Work piece size capability 300mm diameter x 250mm height

Our capabilities also go beyond knowledge of 5-axis milling. We can mill complex materials across a variety of alloys and plastics—including complex stainless and nickel alloys.

LOCATION

Evden Enterprises

2000 Wellmar Dr

Ukiah, CA 95482

(707) 462-0375

© Evden Enterprises.

All Rights Reserved.

D2P Web Design

BUSINESS HOURS

| Monday: | 8 AM - 4:30 PM |

| Tuesday: | 8 AM - 4:30 PM |

| Wednesday: | 8 AM - 4:30 PM |

| Thursday: | 8 AM - 4:30 PM |

| Friday: | 8 AM - 4:30 PM |

| Saturday: | Closed |

| Sunday: | Closed |